LCF has secured access to widebody platforms which provide the opportunity to develop a better understanding of the LCF lift and loading systems - demonstrating loadability and functionality in comparison to the main deck cargo door competition.

Key Considerations:

• The Lift platform assembly (Drive systems, Guide tubes, the MD locking system and the Platform levelling and Drive System Synchronisation Systems).

• The Main Deck floor aperture structure cut out.

• Lower Deck modifications installed to allow the lift platform to descend into a position where containers can be loaded and unloaded.

• Changes made to the Lower Deck CLS systems to enable turning of a container / pallet through 90°

• Installation of sufficient Main Deck CLS system components to be able to demonstrate a realistic complete load / unload cycle.

Focus is on:

Focus is on:

• The ideal locations of the lift operating system controls and their interconnections

• Interphone locations and their use during the load/unload process

• How the novel CLS related safety systems should be configured

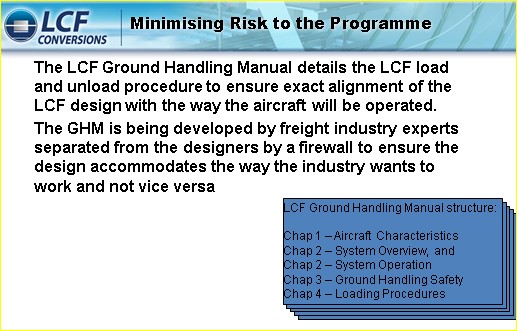

Confirmation that the design and loading procedures comply with the procedures set out in the LCF Ground Handling Manual (GHM) and match the performance criteria set out in the Load / Unload Manual (LUM).

The GHM and LUM have been independently developed by experts from the airfreight operations side of the business together with the designers and suppliers of the CLS to define the ‘best practice’ operational requirements that the final design must satisfy.

© Eolia Trading Limited. All Rights Reserved.